Should you repair or replace your measuring instrument?

Posted by Philip Hanrahan B.E., B.A., M.I.E.I.; Lucky Sharma B.E. (Elec. Eng.) on 23rd Feb 2023

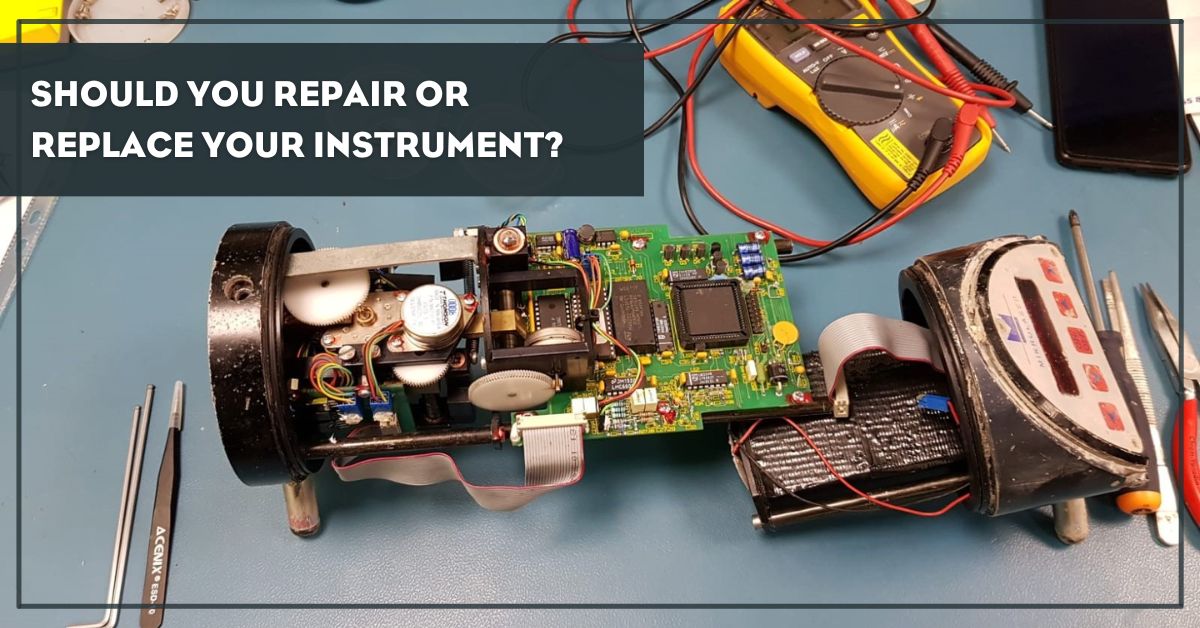

Construction and surveying instruments are often exposed to very harsh conditions. Even though they are made from rugged materials and manufactured to specific standards, they can still be damaged by elements, dropped accidentally or even get run over by a truck or excavator. They can also stop working due to some mechanical or electrical issue that occurs with age, or even missed software updates.

Replacing instruments like rotary lasers or surveying GNSS rovers can be expensive, so it’s always worth looking into repair options first. In most cases experienced technicians can get your equipment repaired and back to you with minimal downtime and at a significantly lower cost.

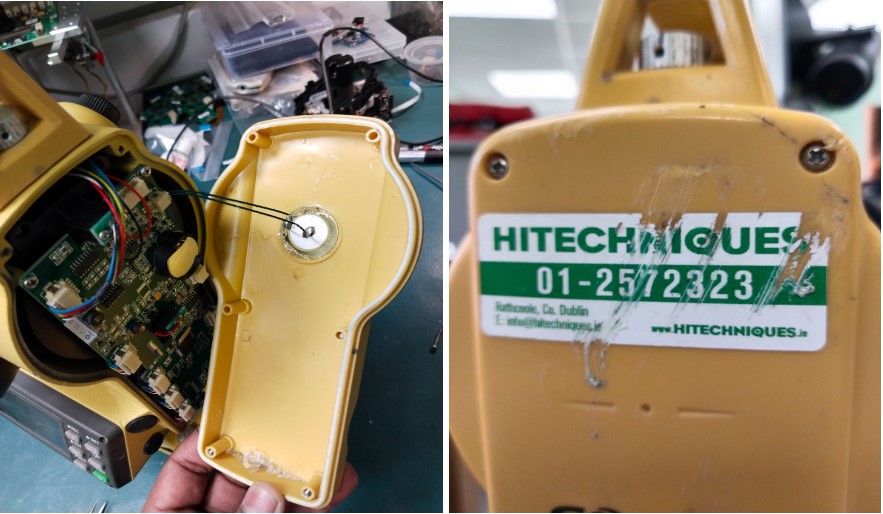

There are a few instances though, when repair is not a viable option. Each instrument coming to the Hitechniques Service Shop is inspected thoroughly, so our technicians can make a list of repairs needed and parts that will have to be replaced. When examining an instrument, they take into consideration three main factors that need to be thought-through, before deciding whether to go ahead with the repair: cost, effectiveness of the repair and the age of the equipment.

Cost

It’s our policy to send repair estimates to each customer before we start working on their equipment, to check if they are ok with the price. Generally we leave the final decision to the customer and proceed with the repair if that’s what they want to do. In some cases, though, the equipment is beyond economical repair and we recommend replacing it instead. This happens if the predicted cost exceeds 75% of the value of a new instrument.

One of our customers has five electronic theodolites they purchased from us. Unfortunately a few days ago one of the theodolite fell down while working and got damaged. The vertical disc of the instrument was completely broken, the chassis was badly jammed, and the vertical angle was no longer visible on the screen. The vertical drive was also not working and the tribrach was bent.

With that much damage the cost of repairs would have been significant and exceeding the 75% of a new instrument’s value. Our technician suggested purchasing a new instrument and offered the customer a discount, if they were to buy from our store. The customer agreed to this offer and purchased a new device from us.

Effectiveness

Surveying and measuring instruments are complex machines built to deliver specific results. They are used by professionals relying on their accuracy and have to perform perfectly. Serious damage to the internal mechanism or electronic components can compromise the instrument’s ability to take accurate measurements.

While most parts can be fixed or replaced, sometimes it’s not possible to assure the same level of efficacy. In such cases it’s best to replace the instrument to avoid costly mistakes.

Age of the instrument

Not every professional needs the latest technology and some hold on to their trusty GNSS receivers or laser levels for many years. There’s nothing wrong with that and it’s great to see so many instruments performing outstandingly for long periods of time. Unfortunately, when such instruments are in need of repair, it can be difficult to find replacement for damaged or worn out parts.

Some final thoughts

When it comes to surveying and measuring instruments, the environmentally friendly “repair instead of replace” approach isn’t always a viable option. Technology becomes obsolete quicker, making repairs harder and more expensive because of complexity of work and poor availability of parts. It also puts more pressure on users to upgrade their equipment in order to stay ahead of the competition. Each case needs to be assessed individually before a decision is made, to assure it makes sense financially and is the best course of action for you and your business.