Things You Didn't Know You Can Do with 3D Machine Control

Posted by Brian Mangan on 12th Aug 2024

When the developers at Unicontrol set out to create their machine control system, they had one primary goal in mind: to get it right the first time. To achieve this, they enlisted the expertise of plant hire contractors who were already utilising GNSS technology on their machines. By engaging directly with these operators, Unicontrol was able to gather invaluable feedback on what users liked and disliked about existing systems. This operator-centric approach has resulted in a ground-breaking product tailored to meet the precise needs of the industry.

A System Built for the Operator

Unicontrol is designed with the operator at its core. It features an intuitive interface and over 80 Customisable features that can be toggled on or off depending on the owner's preferences. This flexibility ensures that the system is as user-friendly as possible, accommodating a wide range of operational needs without overwhelming the user with unnecessary complexity.

Beyond Engineering Drawings

Contrary to popular belief, machine control systems are not just for displaying engineering drawings. Unicontrol excels in scenarios where no pre-existing drawings are available, allowing operators to work efficiently on the fly. The system is so straightforward that operators can become proficient with just a few hours of training. By the end of the comprehensive training and support package offered by Hitechniques, operators will master the system, understanding it thoroughly.

Versatile Surveying Capabilities

One of the standout features of Unicontrol is its advanced surveying capabilities. Operators can perform a variety of surveying tasks directly from the machine, eliminating the need for additional equipment or personnel. Here’s a look at some of the tasks Unicontrol can handle:

Create Simple Drawings:

- Points: Capture precise locations such as the centre of a storm chamber or connections to existing lines.

- Lines: Draw linework for top-of-pipe surveys or boundary lines.

- Splines: Create curved lines for kerb lines or road layouts.

- Circles: Generate circles using two or three points, ideal for defining excavation areas when the centre point is unknown.

Generate Surfaces:

- Flat/Level Surfaces: Specify the desired elevation for digging or filling.

- Complex Surfaces: Create multi-grade surfaces for yards or irregularly shaped banks.

- Foundation Outlines: Confine excavation areas to precise boundaries.

- Surface from Cross Sections: Design roadways, trenches, or car parks with specific elevations and slopes.

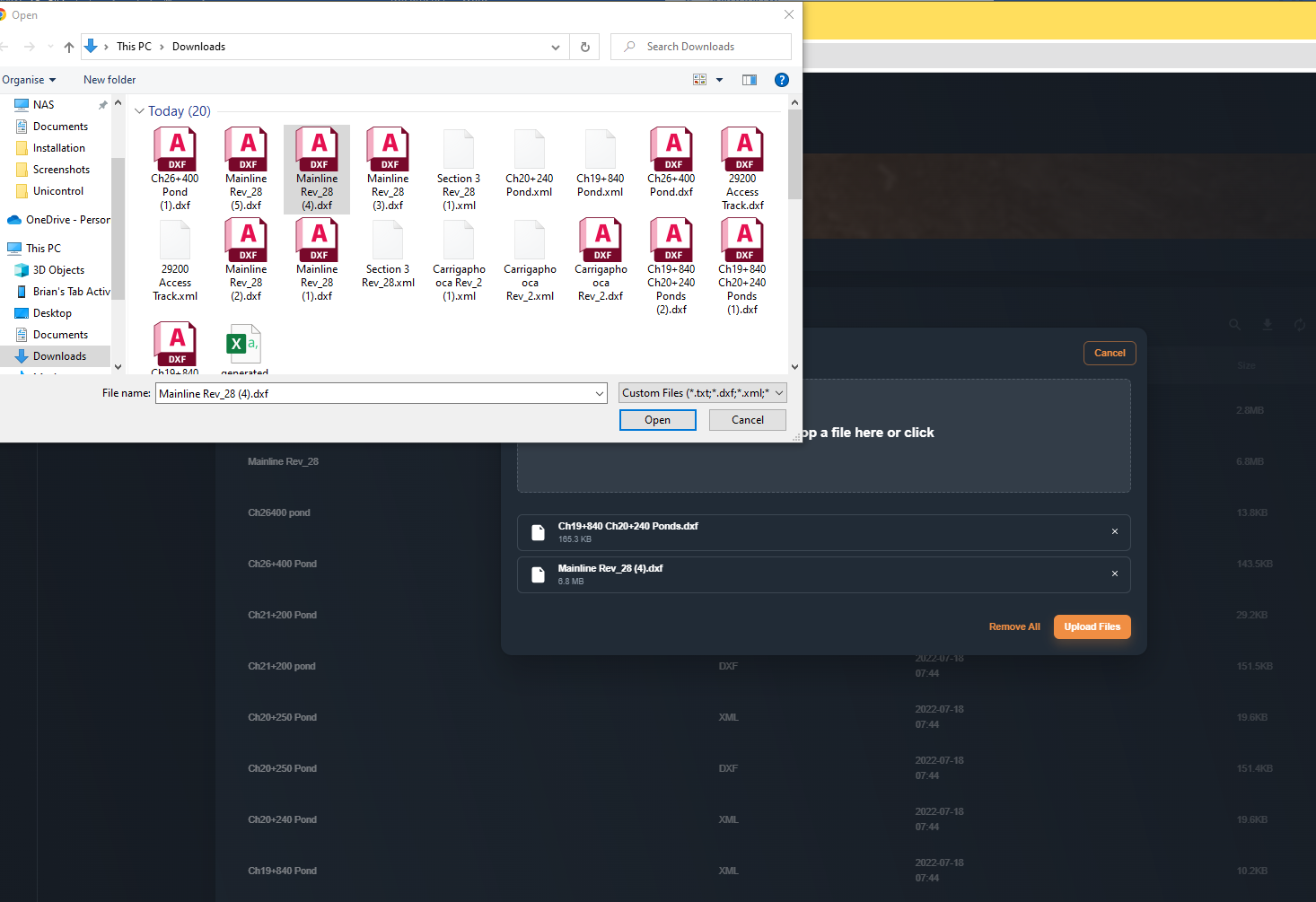

Export Designs and Surveys:

- Cloud Integration: Share surveys with engineers for as-built data or send files to customers for reference.

- Volume Calculation: Accurately measure stockpile volumes by surveying base and top points.

![]()

Slope Functions:

- Point and Percent: Define grades by logging a point and specifying the desired percentage.

- Two Points and a Percent: Establish slopes by selecting start and end points with a specified grade.

- Height-Based Slopes: Determine the grade based on known height values at both ends.

- Fall to Point/Line: Calculate the grade from the bucket to a selected point or line.

Offset Menu:

- Vertical Offset: Easily adjust excavation levels with quick increment values.

- GPS Offset: Align machine GPS with site surveyor data to ensure consistency.

- Side Offset: Move lines or points by a specified distance without needing office rework.

Additional Capabilities of Unicontrol 3D Machine Control

- Remote Diagnostics and Support: Unicontrol's system allows for remote diagnostics and support, enabling distributors to monitor the health of your machines and provide real-time assistance, ensuring minimal downtime and efficient problem resolution.

- Real-Time Data Synchronisation: The UnicontrolCloud facilitates real-time data synchronisation between the office and the field. This ensures that all project data, design files, and as-built information are up-to-date and accessible from anywhere.

- Integration with Various Machine Types: Unicontrol3D is compatible with all types of excavators, including mini-excavators, long-reach excavators, and wheel loaders, making it a versatile solution for different construction equipment.

- Enhanced Project Management: The system provides a centralised platform to manage and monitor all machines on a project, allowing users to view real-time locations and operating statuses of their fleet, which enhances project oversight and coordination.

- Customisable Interface: Unicontrol offers a highly Customisable interface that can be tailored to meet the specific needs and preferences of individual operators, ensuring maximum efficiency and ease of use.

- Short Learning Curve: The system is designed to be intuitive, with a learning curve of just about 30 minutes, allowing operators to quickly become proficient and start using the system effectively.

- Fuel and Labour Efficiency: Using Unicontrol3D can lead to significant reductions in fuel consumption and labour hours by optimising machine operations and reducing rework.

- Paperless Workflow: The UnicontrolCloud supports a paperless workflow by enabling digital design files and project data to be uploaded and shared seamlessly across the entire project team.

- As-Built Data for Quality Control: The system allows operators to generate and share as-built data, which helps in maintaining high standards of quality control and documentation throughout the project lifecycle.

- Versatility in Application Scenarios: Unicontrol3D is effective for a variety of tasks including grading, excavation, dredging, and trenching, providing precise control and real-time feedback to enhance overall project efficiency.

- Support for Tilt Rotators and Swing Booms: The system integrates seamlessly with tilt rotators and swing booms, providing added flexibility and precision in operations involving complex movements.

- Return on Investment: Unicontrol3D offers a cost-effective solution with a high benefit-cost ratio, providing significant returns on investment through enhanced efficiency and reduced operational costs.

Seamless Functionality and Ease of Use

Unicontrol’s functionality is unparalleled, but it is the system's ease of use that truly sets it apart. Operators can quickly find and execute the tasks they need, thanks to the system's intuitive design. This efficiency reduces downtime and increases productivity on the job site.

Training and Support with Hitechniques

At Hitechniques, customer support goes beyond just selling the product. They provide a comprehensive training and support package to ensure every operator can harness the full potential of the Unicontrol system. The training is thorough, covering all aspects of the system, and ensures that operators are confident and capable in using Unicontrol to its fullest extent.

Hitechniques understands that adopting new technology can be daunting. Therefore, their support doesn't end with training. They offer ongoing support to address any issues or questions that may arise as operators become more familiar with the system. This commitment to customer satisfaction ensures that businesses can rely on their Unicontrol system without worry.

Real-World Applications and Benefits

Unicontrol is not just a theoretical improvement; it has tangible benefits on real-world construction sites. For example, the system's ability to create simple surfaces and export designs directly to the cloud streamlines workflows and reduces the need for manual data handling. This not only saves time but also reduces the risk of errors, leading to more accurate and efficient operations.

Moreover, the versatility of Unicontrol's functions means it can be applied in various construction scenarios, from simple earthworks to complex infrastructural projects. The ability to survey using the machine itself and perform volume calculations on the fly gives operators a powerful toolset that enhances their productivity and accuracy.

Experience Unicontrol with Hitechniques

Hitechniques offers a complete training and support package with every Unicontrol system sale, ensuring operators are fully equipped to utilise the system's capabilities. To see Unicontrol in action, contact the team at Hitechniques, book a demo, and discover firsthand how this revolutionary machine control system can transform your operations.

Unicontrol is more than just a machine control system; it is a comprehensive solution designed to meet the modern demands of the construction industry. With its innovative features, user-friendly interface, and unparalleled support from Hitechniques, Unicontrol is set to revolutionise how construction projects are executed. Embrace the future of construction technology with Unicontrol and Hitechniques today.

---

Transform your construction operations with Unicontrol3D machine control system - Contact us today to schedule your demo and experience unparalleled efficiency and precision.