Manual vs Robotic Total Station: Is switching to robotic worth it?

Posted by Philip Hanrahan B.E., B.A., M.I.E.I.; Roch Hanmore B.Sc. on 16th Mar 2021

Using total stations for surveying enabled contractors to measure angles and distances extremely accurately. Latest models are well designed and easy to operate with minimal training required and are a far cry from measuring tape and wooden stakes. They save time, minimise errors, and make jobs much easier and more efficient.

Upgrading your equipment usually brings a learning curve and requires time needed to get up to speed with the new tool. It also requires a big investment. So why would you want a robotic total station when you already have the manual one and a good system in place?

Read more about the fear of upgrading in our article >>

Differences between Manual and Robotic Total Station

There are two types of total stations on the market - manual and robotic. The biggest difference between them is that robotic models have a motor so they can be controlled remotely instead of manually.

Manual total station is a 2-man operation. The instrument must be manually turned, and the prism sighted each time. The EDM (Electronic Distance Measurement) also must be triggered mechanically each time. Robotic total station only needs 1 person to work. It pairs with a tablet and automatically follows the prism and is continuously measuring with the EDM.

With a robotic total station, you can record an average of 600 to even 1500 points in a day (depending on the terrain and other variables). With a 2-man system it's around 250-400 points per day.

A mechanical total station requires more focus on manual tasks, which limits ability to catch mistakes. With the robotic instrument, operator has more freedom and can focus on the site more, quality checking the layout. There is more time available to do these checks with the robot as there is a larger out points and more time to remeasure. This significantly increases overall productivity.

Taking a punt on the investment

If you're in a mid- to large-sized construction company, you no doubt feel the pressure, knowing that the slightest advantage could make-or-break winning the next big contract. In today's world of rapid development using digital layout solutions is a must just to keep up with the competition.

When we talk about investment it is the act of giving time, resources, or effort to a particular task to make it successful.In this case its investing in equipment to survey or set out with a reduction in time and resources being the objective.

At the beginning of all projects, the developer sits down to discuss the time and resources needed to complete the project. Project programmes are usually scrutinised to reduce the project span and hence reducing the labour and resources required (manpower, preliminaries, plant, etc.). There is always emphasis on eliminating errors (Quality Standards) and reducing man hours and fundamentally the labour costs.

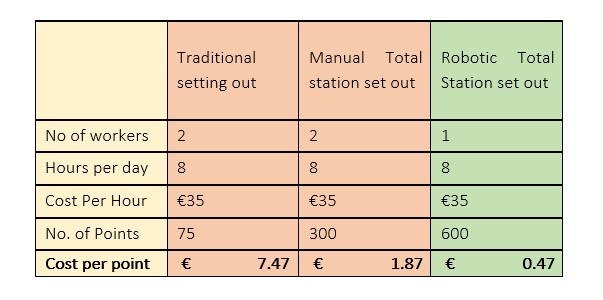

With these objectives in mind, we compared the price of setting out points with a 2-man and Robotic Total station.

This table illustrates the reduction in total cost per layout point. It shows that investing in a robotic instrument will bring savings in the long run.

Once you have your new equipment and your team is trained, you will start saving time and ultimately money thanks to increased accuracy and productivity. You can take on bigger/more complex projects, getting a great return on your initial investment.

---

If you need some advice choosing you next instrument or would like to schedule a Free Demo, give us a call at 01 257 2323.